OUR EXPERTISE

The creative design takes place in our Parisian workshop. We repeat our product development process and prototype evaluation until they reach our required quality standard and perfect proportions.

Our Parisian workshop handles the design, conception, prototyping, and shipping all in one place. Thus, we can always keep an eye on each step of the process to deliver a flawless product. Our Parisian team checks the quality, refines the polish, adjusts the frames, and checks every part of the product before handing it to you.

Every single PETER AND MAY frame must be approved in our Parisian workshop.

CONFIDENT EYEWEAR

We are proud and confident in terms of style and quality. We believe in our

knowledge, experience and transparency, doing our best to reach sustainability.

As French tradition dictates, everything we do boils down to one formula – one that empowers us to create products using the finest materials. The components and materials we use are specifically chosen for their origin, technicality, and durability: Mazzucchelli acetate (Italy), titanium (Japan), Barberini glass lenses (Italy), OBE 5-knuckle hinges (Germany), all to ensure product sustainability.

Each PETER AND MAY product undergoes approximately 95 steps to guarantee optimal results. One of those steps consists in oven-drying the acetates. This resting time allows us to regulate the hygrometry at the heart of the plate from which each frame is produced, resulting in a healthier material in terms of skincare

By subjecting each plate to high pressure before the shaping process, the density of the material is increased, thus improving its durability. The next step is to use digital controls for precision cutting and sculpting, with attention-to-detail down to the contact zones. This is part of our commitment to ensure optimal comfort.

Handle and feel the frames, appreciate their finish. Quality is tested over time.

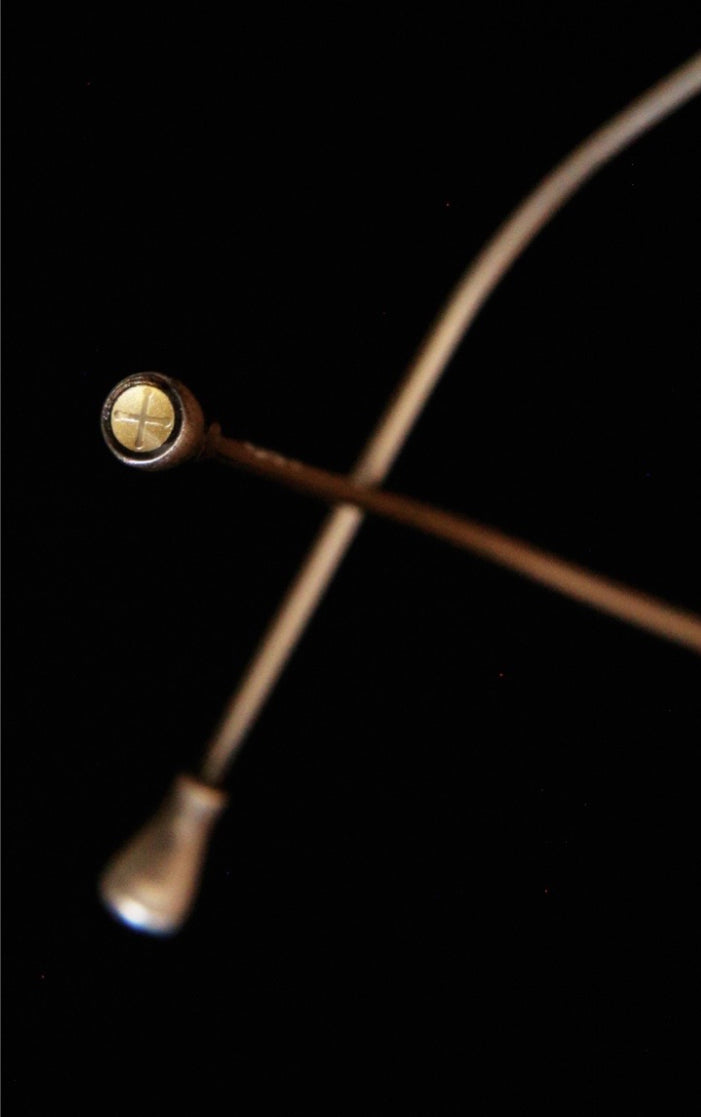

The design of our hinge is an eclectic mix of contemporary aesthetics and traditional technical heritage. Each pivot is supported by quality rivets, along with 5 x-shaped knuckles for a durable end product.

ALWAYS EVOLVING

Our many years of experience combined with the wisdom conveyed by our elders have confirmed our formula. We are continuously nourishing our expertise to make a product we can be proud of.

OPTIMAL CARE

We introduced eco-acetate to our collections in 2021, as soon as this eco-friendly and plant-based thermoplastic material was available in our suppliers stocks.

Our protective lenses are fitted with an internal anti-reflective coating for optimal

protection, and our sunglasses lens tints are custom-made in our partners' workshops.

PRODUCT SUSTAINABILITY

We no longer rely on single-use boxes.

Now, we ship our products in reusable bags made in Italy from BCI certified herringbone fabric – the Better Cotton Initiative is the biggest WWF program

supporting eco-friendly cotton.

Our new case is made of ISO certified recycled materials. This manufacturing process meets strict requirements for chemical restrictions as

well as social and environmental considerations.

The single plastic pouches protecting our products have been replaced with pouches made from TDPA, a family of oxo-biodegradable plastics that disintegrate much faster than common plastic.

OUR WORKSHOP

PETER AND MAY eyewear is designed with the utmost care, and we apply the

highest quality standards to every aspect of our work.

PETER AND MAY provides a sense of community and passion that everyone puts back into their work, just like a family-run business. Our team carefully follows internal quality procedures and inspects each part of the product in our Paris-based workshop before handing it to you.